YASKAWA YASKAWA EA1900N MULTI-ARM WELDING CELL, HUGE, BARELY USED (100 hours)

YASKAWA YASKAWA EA1900N MULTI-ARM WELDING CELL, HUGE, BARELY USED (100 hours)

Location:Imlay City, MI

Description

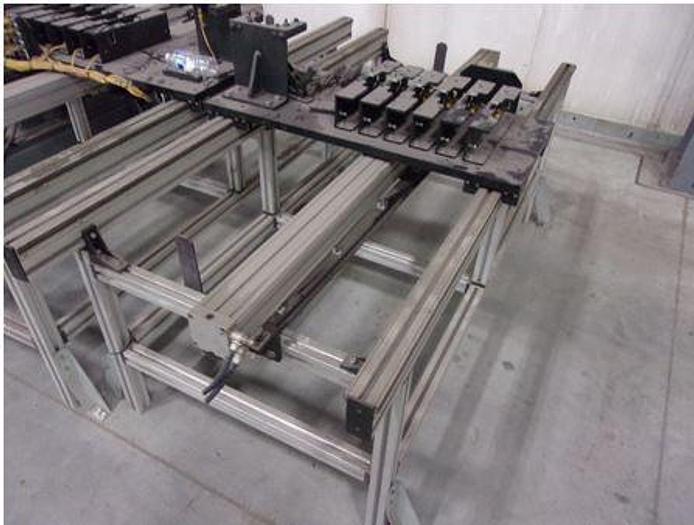

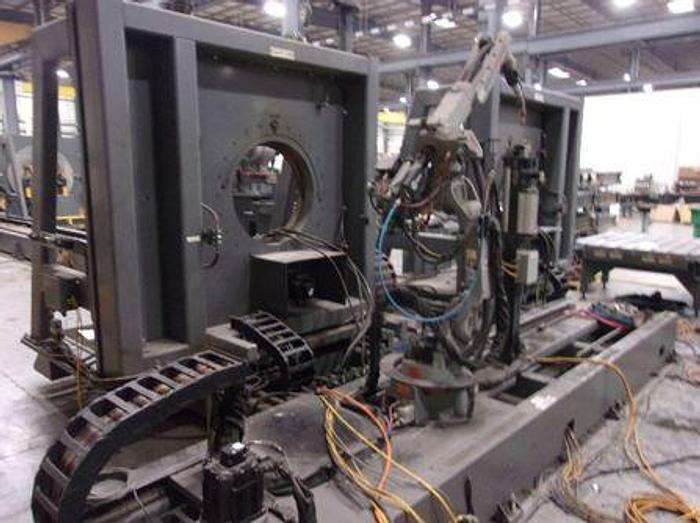

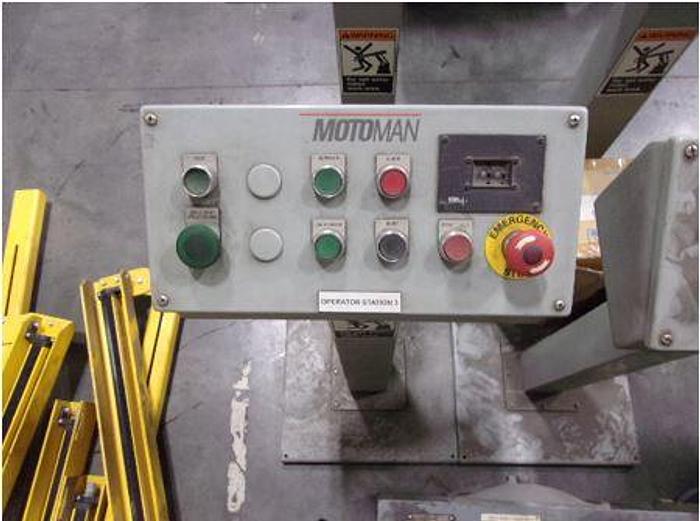

1- USED MOTOMAN EA1900N MULTI-ARM WELDING CELL WITH DUAL THRU HOLE POSITIONERS IDEAL FOR LARGE CYLINDERS OR TUBES DATE OF MFG STOCK NUMBER:103969 ====================================== SPECIFICATIONS WHILE OBTAINED FROM SOURCES DEEMED RELIABLE ARE SUBJECT CHANGE WITHOUT NOTICE AND TO VERIFICATION BY BUYER: THIS IS A VERY LARGE CELL WITH ONLY 100 HOURS OF USAGE. ESTIMATED REPLACEMENT COST: $1,000,000 EQUIPPED WITH: (3) EA1900N GMA W ROBOTS W/ NX100 CONTROLLERS (3) MILLER AUTO AXCESS 450 WELDING POWER SUPPLIES TOOLSIGHT TORCH ALIGNMENT TREGASKISS REAMER/SPRAYER NOZZLE CLEANING STATIONS WATER CIRCULATORS MOTOMAN TOUGH GUN TORCH PACKAGES (1) UP50N W/ NX100 CONTROLLER AND END OF ARM TOOLING FOR MATERIAL HANDLING (1) 33 FOOT LONG RTU UNIT WHICH CARRIES (1) EA1900N AND (1) UP50N, RACK AND PINION DRIVEN (2) 10 FOOT LONG RTU UNITS WHICH EACH CARRIES (1) EA1900N, RACK AND PINION DRIVEN (2) THRU HOLE SERVO DRIVEN TRUNNIONS, 28" THRU HOLE DIAMETER, 3 kW EXTERNAL AXIS KIT WITH HYDRAULIC CLAMPING DETAIL MOUNTING SURFACE ON EACH FACEPLATE (4) OPERATOR STATIONS (4) LARGE WORK SUPPORTS (2) LARGE ROLLER BASES 2. SYSTEM COMPONENTS Description 3 Motoman EA1900N GMAW Robots • Specifically designed for arc welding applications • Welding torch cable is routed through the arm • Six axes of control • 3-kg (6.6-lb) payload capacity • Maximum (p-point) reach of 1,904 mm (75") • Relative positioning accuracy of ±0.06 mm (±0 .002") • Please see attached data Motoman HP50 Material Handling Robot • Six axes of control • 50-kg (I 10.3-lb) payload capacity • Maximum (p-point) reach of 2,046 mm (80.6") • Relative positioning accuracy of ±0 .07 111111 (±0. 00 3" ) • Please see attached data 4 NX I 00 DR2C Robot Controllers • Three EA robot controllers and one HP robot controllers in terfaced as two single controllers with one programming pendant per pair; includes equipment packages to separate controllers for individual control, if desired 3 Robot Servo Tracks • Servo rack-and-pinion drive • One 11-meter stroke track for EA1900N and HP50 robots, two 3.0-meter tracks each with an EA1900N robot • Include s external axis package mounted in NX I00 controller 3 Miller Auto Axcess Weld Packages • Auto Axcess 450 Power Source Output Rating Welding Amps: 450 Volts:.......... 38VDC Duty Cycle:... 100% Hertz:................. 60 Input Rating Line Voltage:. 208/230/460/575 Line Amps:............. 67/59/29/23 Input power:3- Phase, 23.SkVA • Miller interface to NXI00 controller • Four-roll wire feeder and feed rolls • Interconnecting cables • Please see attached data 2 ComArc Seam Packages • One dual- robot package (EA1900N robots R3 and R4) and one sing le robot package (EA1900N Robot R2) • Seam tracking • 200V touch sensing function 3 Weld Dress-out Packages • 4/0 weld cables and necessary hoses Description 3 Motoman Tough Gun® Torch Packages • Specific to EA-series robots 550-amp (CO2 @I 00% Duty cycle) Water-cooled GMAW torch • Wire brake • Safety clutch and start-up kit 3 Tregaskiss Reamer/Sp rayer Nozzle Cleaning Stations Stand-alone device • Pneumatic motor-driven reamer cleans the torch nozzle • Sprayer for anti-spatter compound • Wire cutter 3 Water Circulators 3-gallon tank • Heavy-duty, gear-type pump • Fan-cooled heat exchanger • Water flow sensor 3 Tool Sight™ Comprehensive Torch Alignment Packages Tool Sight gauge assembly • Torch alignment pin Motoman PMT and Relative Job software • Tool Update software • Instruction manual • Please see the attached data 2 Deluxe Accessory Stand • 36" floor pedestal stand • Mounting hardware for torch nozzle cleaner and wire cutter • Junction box for wire termination • Filter regulator unit • Common cable to NXJOO controller 1 Custom Accessory Stand • Mounted from side of robot riser • Mounting hardware for torch nozzle cleaner and wire cutter • Junction box for wire termination Filter regulator unit • Common cable to NX100 controller Custom End-of-Ann Tool (EOA T) • For HP50 robot Custom 2 axis compliance pneumatic device with 3-jaw pneumatic gripper used to capture the boss or bracket or elbow sub-assembly. Electrical and pneumatic package 4 Through-hole Positioners • Dual servo -drive n positio ners; two on 16"-stroke slides (tailstock) 28" diameter through-hole Hydraulic clamping detail mounting surface on each positioner face plate 3.0 kW external axis kit FOB OHIO EQUIPPED WITH: (3) EA1900N GMA W ROBOTS W/ NX100 CONTROLLERS (3) MILLER AUTO AXCESS 450 WELDING POWER SUPPLIES TOOLSIGHT TORCH ALIGNMENT TREGASKISS REAMER/SPRAYER NOZZLE CLEANING STATIONS WATER CIRCULATORS MOTOMAN TOUGH GUN TORCH PACKAGES (1) UP50N W/ NX100 CONTROLLER AND END OF ARM TOOLING FOR MATERIAL HANDLING (1) 33 FOOT LONG RTU UNIT WHICH CARRIES (1) EA1900N AND (1) UP50N, RACK AND PINION DRIVEN (2) 10 FOOT LONG RTU UNITS WHICH EACH CARRIES (1) EA1900N, RACK AND PINION DRIVEN (2) THRU HOLE SERVO DRIVEN TRUNNIONS, 28" THRU HOLE DIAMETER, 3 kW EXTERNAL AXIS KIT WITH HYDRAULIC CLAMPING DETAIL MOUNTING SURFACE ON EACH FACEPLATE (4) OPERATOR STATIONS (4) LARGE WORK SUPPORTS (2) LARGE ROLLER BASES FOB OHIO

Specifications

| Manufacturer | YASKAWA |

| Model | YASKAWA EA1900N MULTI-ARM WELDING CELL, HUGE, BARELY USED (100 hours) |

| Condition | Used |

| Stock Number | 103969 |